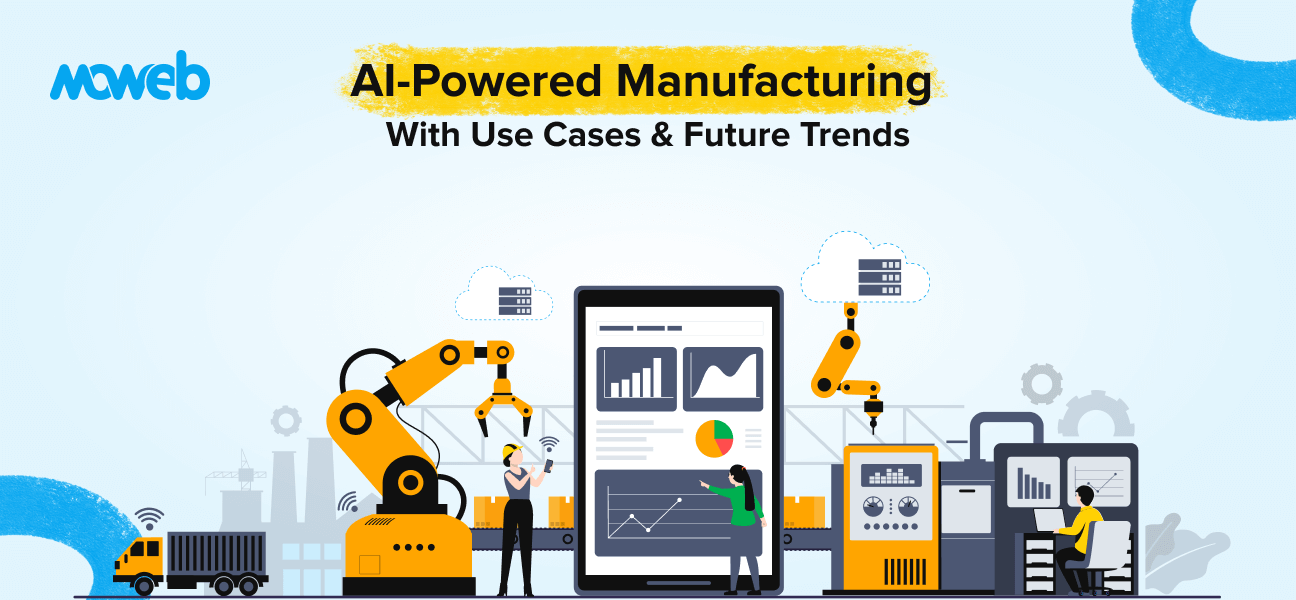

Manufacturing is no longer a promise of the future – it is a reality of today. Manufacturers are using accessible AI to combine automation and data. This helps them make quicker and smarter decisions on the shop floor. From energy management to quality control, use cases are vast and expanding.

With real-world benefits, such as reduced inactivity time and optimized workflows, the use of AI in manufacturing is rapidly becoming a necessity and not a luxury. In this blog, we will look at why artificial intelligence matters in manufacturing. We’ll share real examples and discuss future trends to watch for in 2025. Let’s dive into this industrial transformation.

How AI is Changing Manufacturing Industry

AI is increasingly being adopted in factory operations and is moving beyond pilot programs. The following ways are presented in which AI is revolutionizing manufacturing:

- AI is moving beyond pilots: Although previously applied to pilot projects, Artificial Intelligence in manufacturing is now being included comprehensively in routine operations in the production lines.

- Smart decision making: Manufacturers today are using AI to make real-time, data-oriented decisions rather than relying on analysis or manual assumptions.

- Greater production efficiency: AI use in the manufacturing sector means that machines operate for prolonged periods with less dismissal, thus increasing general production.

- Lower downtime: AI software recognizes when machines will probably fail, allowing teams to repair defects before they become failures.

- Improved forecast: From the programming of materials to customer demand, the artificial intelligence use in manufacturing sector assists in precise forecasting.

- Automated quality control: The cameras used in quality control are AI-based and see flaws in products better than humans used to see.

- Savings on labor costs: Automation promoted through AI reduces unnecessary human labor, which saves time and finances.

- Improved quality: AI follows a trend in a product’s quality and minimizes the impact of human error.

- Flexibility: AI enables the factories to reorganize quickly due to the changes in supplies or special orders.

- Scalable innovation: Small or large factories profit from AI tools that grow with business expansion.

Want to Explore AI in Manufacturing Without the Guesswork?

See how an AI and ML Development Company can help you turn raw data into real-time decisions.

The Top 10 Applications of AI in Manufacturing

AI in manufacturing leads to real changes. These changes create more innovative, responsive, and streamlined maker models. With the increasing adoption of AI by manufacturers, these cases of use will be the norm in the manufacturing sector of AI.

1. AI-Based Root Cause Analysis

One of the most useful AI applications in manufacturing is to determine the causes of repeated process failures. AI systems analyze past data. They pinpoint where and why breaks occur. This helps avoid wasting time and reduces errors. This allows producers to minimize expensive stops and optimize long-term process stability. AI finds small patterns in many variables using automatic analysis. This gives manufacturers valuable insights for ongoing improvements.

2. AI for Inventory Optimization

Smart AI Systems boost how businesses store and move inventory in the plant. Artificial intelligence can help control sales trends and determine the shipping schedule. Therefore, it retains the right level of supply without excessive or running out of stock. This retains storage space and minimizes waste and expenses. With the AI use case in manufacturing, manufacturers receive greater visibility and control of their supply chain.

3. AI-Based Demand Prediction

AI-powered demand forecasts use real-time data. They look at past sales channels, market trends, and social media. These predictions are much more accurate than usual models. With this AI in manufacturing examples, companies can plan production calendars, workforce, and raw material requirements more effectively, avoiding too much or stockpiling.

4. Load Balancing of the Production Schedule Using AI

AI analyzes workload, machine capacity, and deadlines. It evenly distributes production loads across the factory. It prevents bottlenecks and reduces the overload of specific equipment. Of all the numerous AI applications in manufacturing, load balancing is central to smoother workflow and faster delivery times. It also helps managers relocate dynamically without interrupting the entire production line.

5. Optimization of Energy Consumption

In a powerful business, AI helps monitor and cut power consumption. Smart sensors and AI software analyze patterns to cut wasted energy. This real-world AI use in manufacturing helps sustainability and saves costs. It’s a win-win for manufacturers aiming to be greener.

6. Detection of Anomaly for Safety and Safety

AI constantly checks data from connected devices. It looks for safety risks, system intrusions, or odd device behavior. It can warn you about issues like overheating or strange vibrations before they lead to breaks or safety risks. This AI manufacturing app keeps workers safe and protects equipment in important safety areas.

7. Manufacturing Understanding Through AI Customization

AI allows producers to provide custom products on a scale. Factories can adjust dimensions and functions based on customer data. They do this without disrupting the flow. This goes to the manufacturer. It shows how companies can shift from mass production to flexible delivery of data-driven products.

8. Artificial Intelligence in the Visual Inspection Of Micro-Defects

Compared to human inspectors, AI vision systems never get tired. They use high-speed cameras to look at accessories closely. They can spot tiny flaws like scratches, deformities, or color changes. This AI tool enhances product quality in manufacturing. It reduces errors and makes sure customers get the right items every time.

9. Smart Robotics

Associate robots, or “cobots”, which are run by AI, can work with people in security. They look through activities. Many products get changed to fit their lines and respond to real-time feedback. This growing AI in manufacturing example where robots do not require cages or isolation, but effectively work with human labor.

10. AI-Operated Warehouse Traffic Management

The AI technology improves warehouse traffic flow. It cuts down delays and conflicts between forklifts and delivery robots. This manufacturing AI use case helps save storage space. It speeds up order supply and makes worker safety better. It is beneficial for prominent, high-capacity features.

Related Post: How AI Is Transforming Supply Chain Management

Future Developments in AI That Will Shape Manufacturing in 2025 and Beyond

New technologies will also revolutionize the manufacturing industry of AI over the next few years, beginning from 2025. These latest trends will render manufacturers more innovative, quicker, and quicker and sustainable:

- Digital Twins + AI: Companies are already developing digital twins, replicas of simulated machinery or manufacturing lines. With Artificial Intelligence in manufacturing, these twins mimic how systems will function in various circumstances, so that teams can experience, and adjust them, and optimize them before making changes in the real world.

- Edge AI for real-time decisions: Edge computing enables processing directly on the machines. This way, they can make instant decisions without needing cloud access. In future, it expects more factories to use edge devices. This will help them act faster and reduce delays.

- Integration of IoT and AI: Integrated Sensors (IoT) with Smart Factories and Intelligent Factories. This convergence enables real-time tracking and machine-to-machine communication. It also allows predictive analytics for more intelligent and more automated production.

- Generative AI in R&D: Designers use generative AI to accelerate product development. AI simulates product behavior. AI tests different versions and minimizes physical prototypes. Idea to production, it accelerates the process.

- Scalable AI platforms: Cloud-native platforms are bringing AI manufacturing industry, even to small and medium-sized factories. Platforms offer scalable prices, plug and play, and rapid deployment.

- Upskilling the workforce: AI is not taking the jobs of people; it is assisting them. Companies are investing in worker education to work with AI tools, creating new jobs and smarter work functions.

Connect with Moweb Professionals to Create Wiser Manufacturing Solutions

Click here to learn MoreConclusion

AI in manufacturing processes is not a trend anymore; it is an actively reshaping change that is redesigning the work of manufacturing worldwide. Industrial use of AI is also evident in daily life, like predictive maintenance and energy efficiency.

The good news? These technologies are no longer unique to large companies-small and medium-sized companies are using them.

What distinguishes AI in manufacturing from hype is that it is grounded in real effects, no longer hype. It’s approximately higher decision-making, more safety, and optimizing every step of the manufacturing method.

FAQs

1. How is AI transforming the manufacturing industry in 2025?

AI is revolutionizing manufacturing in 2025 by enabling smarter automation, real-time quality control, predictive maintenance, and optimized supply chain management. Manufacturers are using AI to reduce downtime, improve productivity, and adapt faster to changing market demands.

2. What are some real-world use cases of AI in manufacturing?

Real-world use cases include automated visual inspection using computer vision, predictive maintenance through machine learning, demand forecasting, robotic process automation (RPA), and AI-driven production scheduling to reduce bottlenecks.

3. What are the benefits of using AI in manufacturing operations?

AI improves efficiency, minimizes operational costs, enhances product quality, enables real-time monitoring, and helps in decision-making by analyzing large datasets. It also contributes to sustainability by reducing energy consumption and material waste.

4. Are AI solutions affordable for small and medium manufacturers?

Yes, with the rise of cloud-based AI platforms and scalable solutions, even small and mid-sized manufacturers can adopt AI technologies without significant upfront investment. Many tools offer modular pricing and integration with existing systems.

5. What are the future trends of AI in manufacturing beyond 2025?

Future trends include AI-powered digital twins for factory simulation, autonomous robots with adaptive learning, hyper-personalized manufacturing, and increased use of generative AI for design and prototyping. Edge AI and collaborative robots (cobots) will also gain momentum.

Found this post insightful? Don’t forget to share it with your network!