By 2025, nearly 80% of supply chain operations will be driven by AI-powered analytics. However, according to Gartner, only 10% will unlock its full competitive advantage.

AI adoption in supply chains has surged by 270% between 2020 and 2023, according to a McKinsey Global Survey. And yet, inefficiencies still cost global supply chains a staggering $1.9 trillion annually.

The gap between AI adoption and AI mastery is growing. Companies that merely integrate AI won’t win; the ones that operationalize it across forecasting, inventory, logistics, and resilience will redefine industry leadership.

From dynamic inventory management to predictive maintenance and sustainable logistics, AI in supply chain management isn’t just optimizing operations, it’s reshaping the rules of the game.

The real question is: Will your artificial intelligence in supply chain management lead or lag? Read ahead to find out.

Understanding AI in Supply Chain

Artificial Intelligence (AI) and Machine Learning (ML) are no longer future concepts in supply chain management. They are becoming essential tools that help businesses move from reactive firefighting to predictive, data-driven decision-making.

In simple terms, AI in the supply chain means empowering systems to think, learn, and act based on real-time information without constant human supervision. It allows supply chain leaders to anticipate disruptions, optimize operations, and unlock entirely new levels of speed and efficiency.

The integration of artificial intelligence in supply chain management operations is creating smarter, faster, and more efficient logistics networks worldwide.

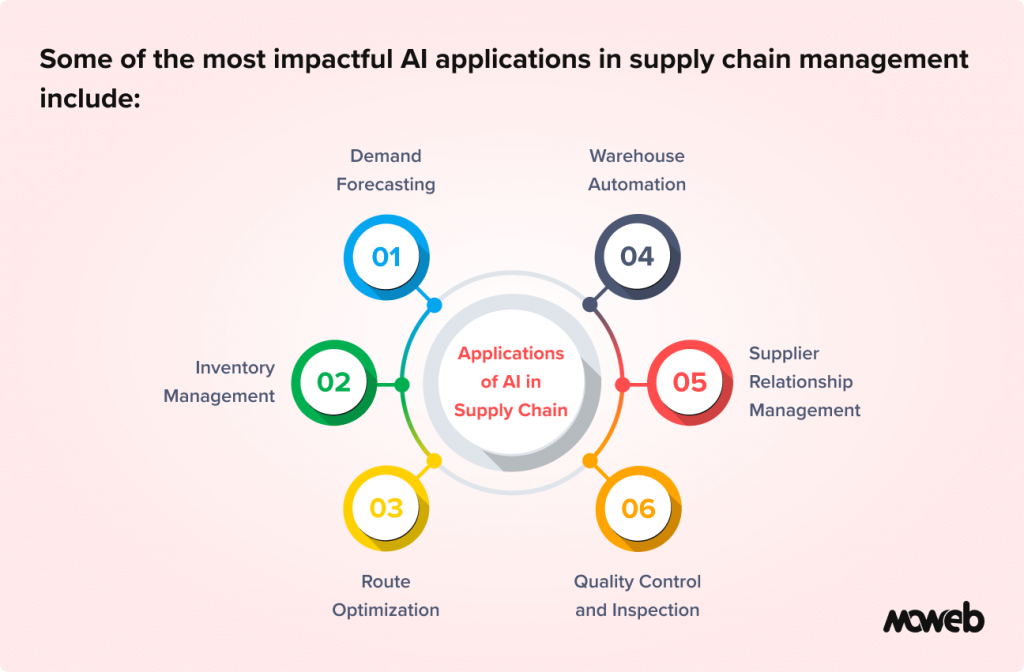

Some of the most impactful AI applications in supply chain management include:

- Predictive Analytics: AI models analyze sales patterns, supplier trends, and even weather data to forecast demand and potential risks with remarkable accuracy.

- Automation: Smart systems handle repetitive tasks such as inventory updates, freight billing, or purchase order management, freeing teams to focus on strategic priorities.

- Prescriptive Analytics: Beyond prediction, AI recommends specific actions like rerouting shipments or adjusting procurement based on evolving real-world scenarios.

Today, modern supply chain management software development revolves around embedding these AI capabilities deeply into platforms. From dynamic routing and predictive maintenance to real-time inventory optimization, supply chain management AI is no longer an add-on. It is becoming the core engine that drives resilient, scalable, and intelligent supply networks.

Looking to modernize your supply chain operations? At Moweb Technologies, we craft custom Supply Chain Solutions

Connect With Our TeamHow AI in Supply Chain Solves Critical Pain Points

Let’s look at the key areas where AI is actively eliminating old bottlenecks and unlocking new opportunities.

Smarter Demand Forecasting and Inventory Optimization

Historically, demand forecasting relied heavily on past sales data and seasonal trends, making it prone to errors. Today, AI supply chain software ingests real-time market signals, social trends, weather patterns, and even competitor activities to forecast demand with far greater precision.

Amazon, for example, uses machine learning models that have helped reduce overstocks and stockouts by nearly 30%. The result is a leaner, more resilient inventory strategy that lowers holding costs and boosts customer satisfaction.

AI in supply chain systems predicts stock needs with 95%+ accuracy, minimizing waste and stockouts.

Predictive Maintenance with AI and IoT

Equipment failures used to mean unexpected downtime, costly repairs, and broken supply chain continuity. Now, AI combined with IoT sensors continuously monitors fleet and machinery health, predicting failures before they happen.

Organizations leveraging predictive maintenance have reduced downtime by up to 25%, proving how AI in supply chain management goes beyond logistics to enhance operational efficiency. Fleet managers no longer wait for breakdowns; they act proactively, scheduling maintenance during off-peak times and extending equipment life.

Supplier Risk Management with AI Algorithms

In a world of global sourcing and political instability, managing supplier risks manually is impossible. AI uses Natural Language Processing (NLP) to scan millions of news articles, weather alerts, financial statements, and geopolitical updates in real time.

When a critical supplier faces a disruption risk, AI algorithms detect it early, allowing companies to reroute orders, diversify sourcing, or adjust inventory strategies without scrambling at the last moment.

Real-Time Inventory Visibility and Optimization

Traditional inventory systems offer a historical snapshot. AI-driven inventory management provides a live, breathing view of stock levels across warehouses, stores, and transit routes.

It continuously analyzes consumption patterns, predicts restock needs, identifies slow movers, and suggests optimal stock levels based on dynamic demand fluctuations. Additionally, AI monitors the health of storage equipment, ensuring predictive maintenance for critical assets like refrigerated units and automated picking systems.

Last-Mile Delivery Reinvented: AI’s True Game-Changer

The last mile has always been the most expensive and unpredictable part of logistics. AI is turning it into a competitive advantage.

Dynamic routing tools like Locus.sh use real-time traffic data, weather updates, and customer preferences to optimize delivery routes on the fly. Companies using these AI-driven solutions have reported up to 18% savings in delivery costs, along with faster and more accurate deliveries.

Sustainability Through AI-Optimized Supply Chains

Sustainability is no longer a buzzword; it is a boardroom priority. AI helps companies shrink their carbon footprint by optimizing transportation routes, warehouse energy usage, and even packaging material selection.

AI models can recommend energy-efficient transit paths, consolidate shipments to reduce trips, and suggest recyclable materials that meet both regulatory and branding requirements. By using AI in logistics and supply chain, companies can cut emissions, lower energy costs, and build stronger ESG narratives.

Logistics and Transportation: Speed, Visibility, and Cost Reduction

AI has revolutionized every layer of logistics management.

It enables:

- Real-time tracking and predictive ETA updates so customers always know when to expect their deliveries.

- Warehouse automation through robotics and smart picking algorithms that reduce picking times and minimize human error.

- Dynamic freight auditing, automatically verifying bills and streamlining payments without manual intervention.

How AI can solve your supply chain challenges? Moweb specializes in delivering scalable AI solutions for logistics.

Talk to Our Experts TodayGenerative AI Impact on Supply Chain Management

Generative AI is pushing supply chains beyond basic automation into a new era of intelligent decision-making and resilience building. It is not just helping businesses move faster, but also preparing them for the unexpected.

Scenario Planning Gets Smarter

With Gen AI, companies can simulate complex disruption scenarios like port strikes, pandemics, or sudden supplier failures. This allows supply chain leaders to stress-test their networks, identify vulnerabilities, and develop contingency plans before real crises hit.

AI Copilots for Procurement

Generative AI is transforming procurement by drafting contracts, automating RFPs, and even recommending negotiation strategies based on supplier history. Teams now move from months-long processes to streamlined, data-driven decisions in days.

Real-World Applications Taking Shape

- Demand Forecasting and Inventory Optimization: Adaptive models adjust forecasts as new signals emerge.

- Warehouse Automation: AI designs more efficient layouts, optimizes picking routes, and reduces fulfillment time.

- Real-Time Shipment Tracking and Logistics: Predictive models not only track shipments but forecast potential delays, offering alternative routes before problems escalate.

Related Post: Supply Chain Best Practices

How AI is Transforming Modern Supply Chains

Smarter Supply Chains with Scenario Planning

What happens if a major supplier suddenly drops out or demand spikes unexpectedly? With advanced simulation tools, businesses can now run “what-if” scenarios to test responses before they happen in real life. Whether it’s rerouting shipments or switching suppliers, this approach helps teams prepare with confidence—turning unpredictability into opportunity.

Stay Ahead with Real-Time Alerts and Insights

Imagine being able to spot issues before they cause delays. Real-time monitoring tools keep an eye on everything from warehouse operations to global shipping routes. If something goes off track—like weather-related delays or supplier disruptions—teams get immediate alerts, giving them time to act fast and avoid costly setbacks.

Your Digital Teammate: Assistants That Make Work Easier

Digital assistants are becoming part of the everyday supply chain workflow. These helpful tools support tasks like procurement tracking, inventory management, and delivery scheduling—all from within the platforms teams already use. They guide staff step-by-step, reduce manual errors, and save hours of back-and-forth.

Building Self-Healing, Adaptive Supply Chains

For industries like healthcare and food, keeping products at the right temperature is non-negotiable. Technology is helping businesses monitor conditions across every stage of the journey. With real-time alerts and predictive tools, companies can prevent spoilage, maintain quality, and improve overall product safety.

Personalized Planning for Every Customer

Forecasting no longer stops at regions or product categories. Businesses are now tailoring their planning based on individual customer preferences, seasonality, and buying patterns. This level of detail helps avoid overstocking, improves customer satisfaction, and supports faster delivery timelines.

Real Results: The Business Benefits of AI in Supply Chains

Adopting new tech is only worthwhile if it drives measurable outcomes. Businesses that embrace intelligent supply chain tools are seeing up to 30% fewer delays, better forecasting accuracy, and faster issue resolution. These improvements directly translate into reduced costs, happier customers, and stronger business performance.

Benefits of Implementing AI in Supply Chain Management

Hyper-Personalized Customer Experiences

AI predicts individual preferences, enabling tailored product recommendations and delivery options.

Talent Upskilling

By automating repetitive tasks, AI allows human workers to focus on strategic initiatives and decision-making.

Faster Decision-Making

Real-time data insights help businesses reroute shipments instantly during crises, like during the Suez Canal blockage.

Increased Efficiency and Productivity

AI-driven automation cuts operational costs and boosts overall supply chain performance.

Driving Innovation and Competitive Advantage

Early AI adopters in supply chain management are leading the market by innovating faster and adapting smarter.

Greater Supply Chain Resilience and Agility

From risk prediction to autonomous rerouting, AI builds stronger, more flexible networks.

AI Related Post: AI in Agriculture: Real-World Use Cases and Software Integration

How Intelligent Tools Are Reinventing Supply Chains

Modern supply chain management platforms are equipped to:

- Spot patterns in consumer behavior and anticipate demand, keeping shelves stocked and reducing waste.

- Track inventory levels and product movement across every warehouse and retail location, providing instant updates without human intervention.

- Optimize delivery schedules and routes using live traffic data and customer preferences, saving both time and resources.

- Deliver instant, personalized customer support through digital assistants, improving satisfaction and freeing teams for strategic tasks.

Supply chain management AI is more than a buzzword—it’s the backbone of logistics transformation. Solutions built with advanced analytics and automation create lean, adaptive supply chains that quickly detect disruptions, reroute shipments, and streamline the entire process from sourcing to last-mile delivery.

Whether you’re a global manufacturer or a local retailer, integrating these intelligent systems into your operations means faster deliveries, better inventory control, and more robust risk management. The future of ai in supply chain is about combining actionable insights, smart automation, and seamless collaboration to drive value across every link of the supply network.

Embracing this new era of ai and supply chain management ensures companies stay competitive, agile, and ready to thrive in an unpredictable world. Businesses investing in these advanced solutions are redefining what supply chain excellence looks like—focusing on performance, reliability, and innovation at every step.

Challenges for AI in Supply Chain

Change Management and Organizational Adoption

Cultural resistance to automation can slow down AI implementation.

Cybersecurity Risks

AI systems introduce new vulnerabilities that require proactive cybersecurity measures.

Bias and Compliance

Ensuring that AI models are transparent, fair, and meet regulatory standards is crucial.

Data Quality Issues

Poor data quality leads to poor AI performance. Cleaning, integrating, and maintaining data is vital. Tools like Databricks assist in achieving data readiness.

Generative AI is rewriting the rules of supply chain success.

Stay ahead by integrating future-ready AI models into your operations.

Get started with Moweb’s AI solutions

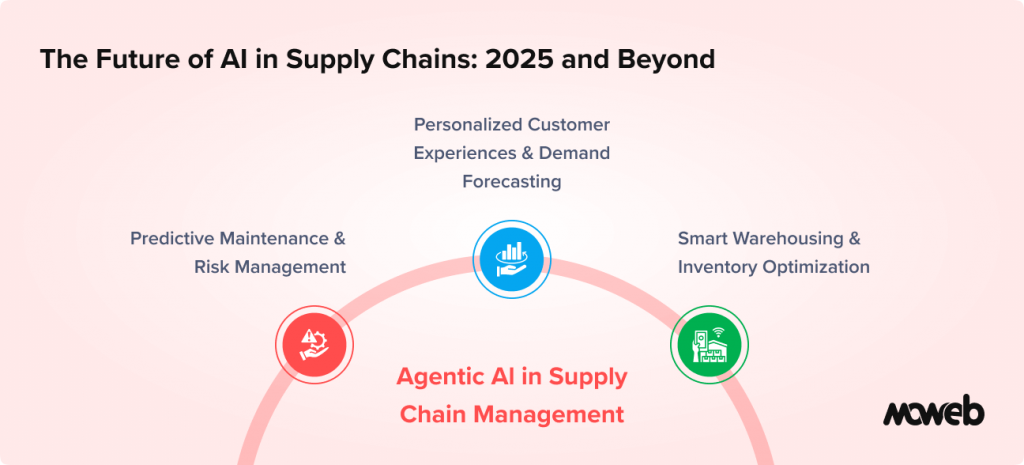

The Future of AI in Supply Chains: 2025

Supply chain management AI is transforming global operations through intelligent automation and data-driven decision making. By implementing supply chain management AI, companies achieve unprecedented visibility, efficiency and resilience across their networks.

Autonomous Supply Chains

Self-correcting supply networks will operate with minimal human intervention. AI will continuously monitor variables like demand shifts, transportation delays, and supplier risks, automatically adjusting operations without waiting for human decisions.

AI + Blockchain

Combining AI and blockchain will ensure tamper-proof, transparent tracking of goods. This fusion will enhance trust across partners, reduce fraud, and allow real-time verification of every transaction and shipment movement.

Quantum Computing

Quantum technologies will solve hyper-complex logistics problems in seconds. Complex routing, inventory balancing, and production scheduling that today take hours to model could soon be optimized almost instantly, unlocking new levels of efficiency.

Generative AI for Scenario Planning

Generative AI will simulate countless supply chain disruption scenarios to test resilience under extreme conditions. Companies can stress-test strategies against global crises like port closures, raw material shortages, or geopolitical conflicts—before they happen.

Autonomous Supply Networks

Machine-driven decision-making will allow seamless supply chain operations across sourcing, manufacturing, and distribution. Networks will predict, adapt, and act in real time, shifting from being managed assets to self-optimizing ecosystems.

Let Moweb’s team unlock the full value of AI for your unique supply chain

Get in Touch Today!How to Start Your AI Journey in Logistics and Supply Chain

Adopting Artificial Intelligence in supply chain management is not about rushing into the newest tools. It is about building a strong, structured foundation for long-term success. Here’s how to get started the right way.

Choose the Right AI Supply Chain Software

Not all AI solutions fit every supply chain. Focus on selecting AI supply chain software that is tailored to your industry, product type, and operational scale. A retailer’s needs will differ vastly from those of a pharmaceutical company. Look for flexibility, integration capabilities, and industry-specific modules that can adapt to your workflows.

Audit Your Data Quality

AI thrives on high-quality data. Before deploying any AI model, conduct a full audit of your existing datasets. Clean, complete, and real-time integrated data is essential. If your systems are siloed or outdated, AI will only amplify inefficiencies. Investing in data readiness today prevents costly failures later.

Pilot Custom AI Projects

Start small but strategic. Pilot initiatives like AI-driven demand forecasting or predictive maintenance models. A focused pilot lets you test capabilities, gather early wins, and build organizational confidence without risking large-scale disruptions.

Partner with the Right Experts

Collaborating with an experienced technology partner like Moweb can accelerate your AI journey. With expertise in supply chain enterprise software development services and industry-specific AI solutions, Moweb helps businesses move from pilot to scalable deployment with minimal friction.

Track ROI Early and Consistently

AI is only as valuable as the outcomes it delivers. Define clear KPIs from the beginning, such as OTIF (On-Time In-Full) rates, inventory turnover, cost per shipment, and carbon footprint reductions. Continuously measure and optimize to demonstrate tangible business impact.

Building an AI-enabled supply chain is a marathon, not a sprint. Strategic steps today pave the way for operational excellence tomorrow.

Every AI journey starts with a strong foundation.

Let Moweb help you design a roadmap customized for your supply chain goals.

Schedule a consultation

How Modern AI Technologies Are Making Supply Chains More Efficient

Enhanced Demand Forecasting

Machine learning algorithms predict future sales patterns accurately. Today’s systems can sift through mountains of real-time sales data, market trends, and even weather patterns to anticipate future demand with greater accuracy. Businesses now catch demand surges early and stock the right products at the right time, reducing waste and boosting customer satisfaction.

Real-Time Inventory Management

AI enables live stock updates, minimizing inventory gaps. Warehouse and retail managers don’t have to rely on yesterday’s numbers anymore. With always-on tracking, stock levels update instantly across locations, helping teams spot shortages or surpluses before they disrupt operations. Teams can now make confident, fact-based purchasing decisions and avoid costly overstock or out-of-stock issues.

Smart Logistics & Optimized Delivery Routes

Dynamic delivery scheduling maximizes fleet utilization. Logistics tools tap into live traffic updates, weather reports, and customer locations to plot the best delivery paths on the fly. Drivers spend less time stuck in jams, parcels arrive faster, and companies save money on fuel. Delivery windows are shorter, and customers can follow every step of their order in real time.

Warehouse Automation

Robotics and AI streamline picking, packing, and shipping tasks. Modern picking systems, robotics, and smart sorting lines have revolutionized warehouses. Automatic check-in and sorting means fewer mistakes, faster order fulfillment, and staff freed up to handle more strategic work. This not only shortens order cycles but ensures accuracy from receiving to shipping.

Predictive Maintenance

Sensors and predictive analytics extend equipment lifespan and reliability. Fleet managers can now monitor trucks, forklifts, and conveyor belts with sensors that spot problems before they cause breakdowns. Early alerts let teams perform repairs during downtime instead of reacting to surprises—extending the life of equipment and reducing costly interruptions.

AI Chatbots and Virtual Assistants

Customer support bots enhance user experience by providing instant updates. Customers increasingly expect instant answers. Digital assistants are available 24/7 to track orders, handle rescheduling requests, and answer common questions. This boosts satisfaction and allows human support teams to focus on more complex tasks, improving service overall.

Build a Smarter Supply Chain with Moweb

AI in supply chain management isn’t just about automation—it’s about survival.

The competition is already adopting AI supply chain software to unlock efficiency, resilience, and growth. Artificial intelligence in supply chain management is driving a massive shift by enhancing efficiency, reducing costs, and improving decision-making. Forward-looking businesses must embrace AI today to remain competitive tomorrow.

Looking to modernize your supply chain operations? At Moweb Technologies, we craft custom digital solutions that streamline logistics, improve forecasting, and help you respond faster to change.

FAQs

Can small businesses use AI in supply chains?

Yes, AI solutions are highly scalable and accessible for small businesses. Even simple implementations like real-time inventory tracking or AI-driven demand forecasting can significantly improve efficiency, reduce costs, and enhance customer satisfaction without heavy upfront investments.

Can AI reduce supply chain costs?

Absolutely. AI optimizes key processes like inventory management, delivery routing, and warehouse operations. By minimizing overstock, reducing transport miles, and predicting maintenance needs, businesses can achieve substantial cost savings across their supply chain.

What are the benefits of using AI for inventory management?

AI enhances inventory management by providing real-time visibility into stock levels across locations, predicting demand trends accurately, and suggesting optimal replenishment strategies. This leads to fewer stockouts, lower carrying costs, and better customer service.

How can AI help improve supply chain resilience?

AI strengthens supply chain resilience by identifying risks early, such as supplier disruptions or transportation delays. It enables proactive rerouting, inventory reallocation, and dynamic risk management, ensuring minimal impact during unexpected events.

How does AI contribute to sustainability in supply chains?

AI helps businesses reduce their carbon footprint by optimizing shipping routes, minimizing excess inventory, recommending sustainable packaging options, and improving warehouse energy efficiency. These improvements support both environmental goals and cost reduction.

What’s the role of generative AI in supply chains?

Generative AI goes beyond automation by enabling scenario simulations, automating procurement workflows, and helping design more agile, responsive supply chain systems. It plays a key role in improving resilience, efficiency, and innovation across operations.

How can a business start using AI in its supply chain?

Businesses should begin with a digital maturity audit to assess readiness. Starting small with pilot AI projects like demand forecasting helps build momentum. Partnering with experienced providers ensures the right strategy, implementation, and long-term scalability.

Found this post insightful? Don’t forget to share it with your network!