In 2025, supply chain software is no longer just an operational support system, it’s the central nervous system of global trade. With geopolitical volatility, rising customer expectations, and rapid digital transformation, the way businesses approach supply chain management has undergone a seismic shift. According to a report by Gartner, over 80% of supply chain leaders plan to invest in advanced supply chain technologies, including AI and IoT, by the end of this year.

Custom supply chain software is now a strategic necessity. Enterprises need intelligent systems that not only handle logistics and inventory but also provide predictive insights, improve transparency, and drive automation. Off-the-shelf solutions no longer meet the dynamic needs of today’s connected ecosystems. As a result, businesses are increasingly partnering with specialized development teams to build scalable, secure, and intelligent software supply chain best practices tailored to their operations.

Why Supply Chain Software is Critical in 2025

In 2025, supply chain software has evolved into the command center that orchestrates everything from sourcing to delivery. It ensures that every process, every product, and every partner is connected, responsive, and aligned to meet real-world demands.

Time Tracking and Automation Matter

Speed and accuracy are no longer nice-to-have. They are what separate leaders from laggards in competitive markets. Real-time tracking and automation provide the situational awareness and agility needed to handle rapid changes in demand, logistics bottlenecks, or supplier issues.

Automation plays a major role here. It eliminates manual tasks like order reconciliation, inventory updates, and logistics coordination, freeing up teams to focus on strategic work.

Drive Visibility and Trust

Artificial intelligence and machine learning are reshaping supply chain management. AI enables more accurate demand forecasting by analyzing historical sales, market trends, and external signals like weather or political instability. Machine learning constantly refines these predictions, learning from new data to help businesses optimize stock levels, minimize waste, and avoid overstocking.

These technologies also help identify risks early. For example, if a supplier consistently misses delivery deadlines, AI can flag them for review or recommend better-performing alternatives. This kind of insight used to take days of manual analysis. Now, it’s available instantly.

Transparency Across Supply Chain Transactions

Blockchain, on the other hand, tackles one of the supply chain’s biggest challenges—transparency. It provides a tamper-proof record of every transaction across the supply chain. This is especially critical in regulated industries where provenance and accountability matter. With blockchain, stakeholders can trace the entire lifecycle of a product, right down to where a raw material was sourced and how it was handled during transit.

The result is not just more accurate data. It’s a foundation of trust between partners, regulators, and customers. As supply chains become more distributed and global, this trust is becoming just as valuable as efficiency.

The Problem with Traditional Supply Chains—and How Software Solves It

Traditional supply chains were never designed for today’s pace of business. They rely heavily on manual processes, outdated ERP systems, and static planning methods. These systems struggle to keep up with modern complexity. When something goes wrong—like a supplier delay or a shipping disruption—it can take days to detect, understand, and respond.

Modern supply chain software closes this gap. It brings together data from every corner of the operation, analyzes it in real time, and provides teams with clear, actionable insights. Instead of waiting for a monthly report to see what went wrong, managers can now get alerts the moment a shipment is delayed or a forecasted demand spike appears.

Software also enables cross-functional collaboration. Instead of departments working in isolation—procurement in one tool, logistics in another, finance in a third—integrated platforms allow everyone to work from the same data source. This alignment reduces miscommunication and speeds up decision-making across the board.

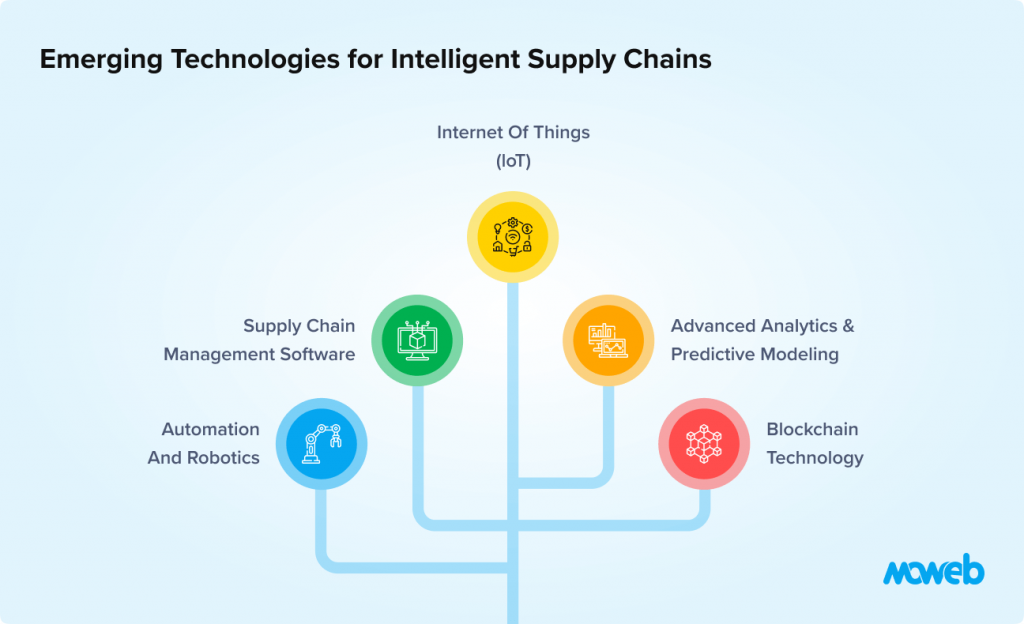

Emerging Technologies for Intelligent Supply Chains

Artificial Intelligence (AI) and Machine Learning (ML)

AI and machine learning in supply chain software allow businesses to transition from reactive to proactive operations. AI-powered forecasting tools process vast amounts of structured and unstructured data—from historical sales to weather patterns—to predict demand with pinpoint accuracy. ML models continuously learn from operational data, improving inventory optimization, reducing wastage, and minimizing holding costs.

Route planning is another area where AI is revolutionizing efficiency. Using real-time traffic and environmental data, AI algorithms determine the fastest, most fuel-efficient delivery paths, which significantly cut logistics costs. These technologies also enhance supply chain risk management best practices by identifying vulnerabilities before they become disruptions.

Internet of Things (IoT) Integration

IoT has become indispensable for achieving end-to-end visibility. From GPS-tracked shipments to smart warehouse sensors, IoT devices provide granular insights into every stage of the supply chain. With over 75 billion IoT devices expected to be connected by 2025, software systems must be capable of ingesting and analyzing high-velocity data streams.

Real-time alerts from temperature sensors in cold chains or RFID tags on high-value goods ensure quality control and prevent losses. Software that supports IoT integration allows supply chain managers to make quick, data-driven decisions and reduce reaction time during unexpected events. This is central to achieving real-time supply chain management best practices.

Blockchain for Transparency and Trust

Blockchain in supply chain management ensures that every stakeholder has access to a shared, tamper-proof ledger. This technology is especially valuable in industries where provenance and regulatory compliance are critical—such as pharmaceuticals, aerospace, and food.

With blockchain, manufacturers can track the journey of a product from raw material to finished goods. Smart contracts automate compliance checks and payments, improving efficiency and trust across suppliers and distributors.

When developing supply chain software, integrating blockchain requires thoughtful architectural planning. Developers must ensure secure consensus mechanisms, on-chain/off-chain data handling, and compliance with data governance frameworks. Still, the payoff is significant: a transparent, secure, and efficient supply chain.

Looking to build a smarter supply chain solution?

Reach out to our experts today and discover how we can transform your operations from reactive to resilient.

Let’s talk

Supply Chain Security Best Practices and Trust in the Supply Chain Ecosystem

As supply chain systems become more digitized, they also become more exposed to cybersecurity threats. Following supply chain security best practices in 2025 is non-negotiable for safeguarding business continuity and customer trust.

Mitigating Vulnerabilities and Penetration Testing

Regular security audits and ethical hacking simulations help identify system loopholes before hackers do. This proactive approach strengthens overall resilience.

Secure Software Development Lifecycle (SSDLC)

Security needs to be integrated into every stage of development—from design to deployment. A secure coding framework, vulnerability assessments, and automated testing ensure threat mitigation early in the pipeline.

API Security

As APIs enable third-party integrations, they become potential attack vectors. Rate limiting, authentication, and tokenization are essential to prevent unauthorized access.

Data Security and Privacy

Encryption at rest and in transit, tokenization of sensitive data, and compliance with GDPR, CCPA, and other regulations should be embedded into the software’s foundation.

Third-Party Risk Management

Vet vendors and service providers rigorously. Ensure contracts include clear cybersecurity requirements and audit rights.

Identifying and Encrypting Critical Data

Not all data is equal. Developers must identify mission-critical data and enforce multi-layer encryption policies.

Related Post: AI In Supply Chain

Best Practices for Supply Chain Software Development in 2025

To build modern supply chain solutions that are robust and future-proof, teams must follow these core best practices for supply chain management:

Adopt AI and Predictive Analytics

Predictive analytics transforms raw data into actionable foresight. Use AI to optimize everything from inventory planning to demand forecasting.

Ensure End-to-End Visibility with IoT

Real-time visibility into supply chain activities ensures swift decisions and fewer disruptions. IoT sensor data must be centralized and visualized through intelligent dashboards.

Prioritize Cybersecurity and Data Protection

A breach can cause millions in losses. Prioritize secure development, constant monitoring, and compliance as part of your DevSecOps culture.

Leverage Blockchain for Transparency

Use blockchain for immutable records, automated contract execution, and enhanced stakeholder trust.

Cloud-Native and Scalable Architecture

Opt for containerized microservices and cloud-native frameworks to ensure high availability, auto-scaling, and global accessibility.

User-Centric Design and Mobile Accessibility

Modern users demand sleek interfaces and mobile-first design. UX/UI must prioritize usability, speed, and accessibility for field agents and executives alike.

API-First Approach for Integration

Ensure seamless integration with ERP, CRM, and legacy systems by building extensible, secure APIs. This API-first mindset accelerates ecosystem adaptability.

Agile and DevOps for Faster Deployment

Accelerate time-to-market through Agile sprints and CI/CD pipelines. Integrate automated testing, containerization, and real-time monitoring to ensure quality at speed.

Ready to Build a Future-Ready Supply Chain Platform?

Explore our Supply Chain Software Development Services designed for real-time intelligence, automation, and growth.

Speak to our experts today

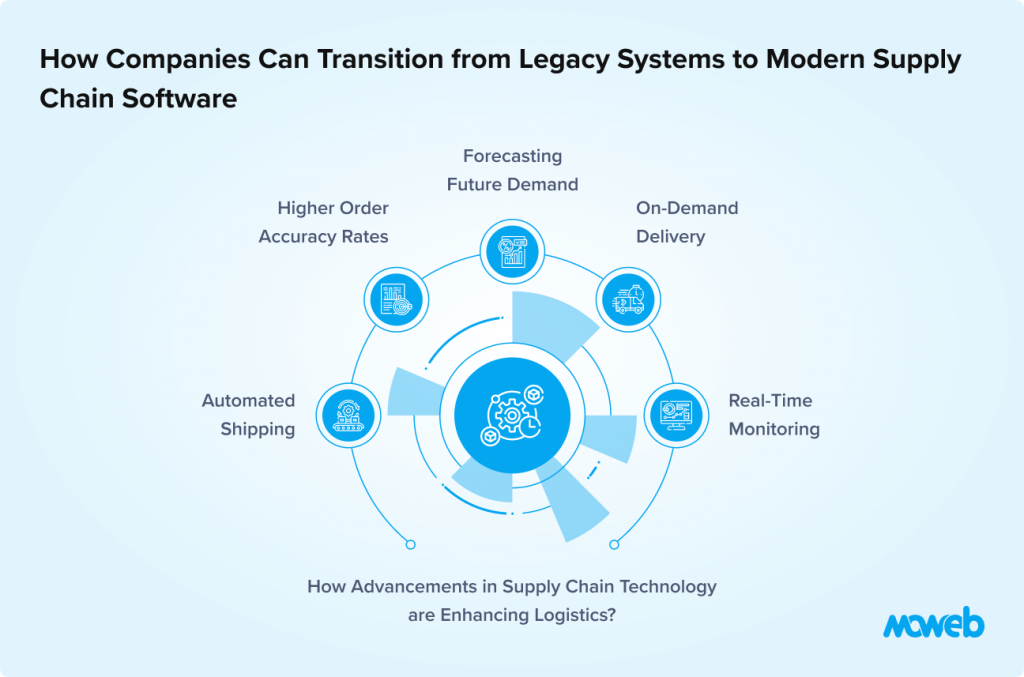

How Companies Can Transition from Legacy Systems to Modern Supply Chain Software

Moving away from outdated supply chain systems can feel overwhelming, but the right strategy ensures smooth adoption.

Assess Current Systems & Identify Pain Points

Start by mapping out existing workflows, tools, and bottlenecks to uncover where legacy systems fall short in speed, visibility, or integration.

Define Clear Objectives & Business Goals

Set specific goals—whether it’s reducing lead times, improving inventory accuracy, or enabling real-time tracking to guide the software selection and development process.

Choose the Right Modern Supply Chain Software Company

Partner with a team that understands your industry, offers long-term support, and has a proven track record of delivering scalable, secure, and intelligent solutions.

Develop a Phased Migration Plan

Avoid the risks of a full-system overhaul by migrating in stages—starting with low-risk modules, testing outcomes, and scaling gradually.

Perfect Data Migration & System Integration

Ensure that all historical and live data is cleansed, validated, and mapped accurately before integrating with other systems like ERP, CRM, or WMS.

Train Employees & Encourage for New Adaptation

Equip your workforce with the tools and training they need to confidently navigate the new platform and embrace digital workflows.

Monitor Performance

Use dashboards and KPIs to track adoption, detect issues early, and continuously optimize system performance after rollout.

Mitigate Risks & Ensure Cybersecurity

Build robust access controls, encryption, and monitoring from day one to protect sensitive data and prevent breaches during and after migration.

How to Choose the Right Development Partner

Your software partner can make or break your digital supply chain transformation. Here’s what to consider:

Experience and Expertise

Look for an AI ML Development Company with proven experience in logistics and supply chain activities. They should understand sector-specific challenges and compliance.

Long-Term Support

Beyond development, the partner must offer maintenance, upgrades, and continuous optimization aligned with evolving supply chain management techniques.

Tech Stack Proficiency

Frontend: React, Angular

Backend: Node.js, Java Spring Boot

Databases: PostgreSQL, MongoDB, TimescaleDB

DevOps: Jenkins, Docker, Kubernetes, Terraform

API/Integration: GraphQL, REST, gRPC

Security and Compliance-First Culture

Ensure that secure development practices and regulatory frameworks are core to their engineering process.

Conclusion

2025 is a transformative year for supply chain operations. From predictive analytics to blockchain-enabled transparency, the modern supply chain is intelligent, automated, and secure. By embracing these supply chain software development best practices, businesses can build resilient ecosystems that adapt quickly and operate efficiently.

The future belongs to agile, data-driven supply chains powered by custom software. Now is the time to invest in systems that don’t just manage workflows but predict, optimize, and lead them. Let’s future-proof your supply chain—get started with Moweb today!

FAQs

What are the most significant technology trends impacting supply chain software development in 2025?

The biggest trends include AI for predictive analytics, IoT for real-time visibility, blockchain for trust, and cloud-native architectures for scalability. These technologies collectively redefine supply chain best practices and improve responsiveness.

What role will IoT play in the future of supply chain software?

IoT enables real-time monitoring of assets, environments, and shipments. It helps in predictive maintenance, inventory tracking, and enhances supply chain risk management best practices by reducing blind spots in operations.

How can AI improve supply chain software performance?

AI improves forecasting, automates workflows, and optimizes logistics decisions. It helps detect patterns in supply chain activities that humans might miss, thereby increasing efficiency and reducing costs.

What are the challenges in integrating new technologies into existing supply chain systems?

Legacy systems often lack compatibility, which leads to integration issues. Data migration complexity, user resistance, and cybersecurity concerns are common hurdles businesses must plan for.

What future technologies will disrupt supply chain software?

Quantum computing, edge AI, and autonomous delivery systems are expected to disrupt logistics and supply chains further. These innovations will enable hyper-efficient, adaptive supply chains in the near future.

Found this post insightful? Don’t forget to share it with your network!